Home » Cd'A oral surgeon pioneers dental implant system

Cd'A oral surgeon pioneers dental implant system

FDA-approved technology assists planning, placement of dental implants

December 1, 2016

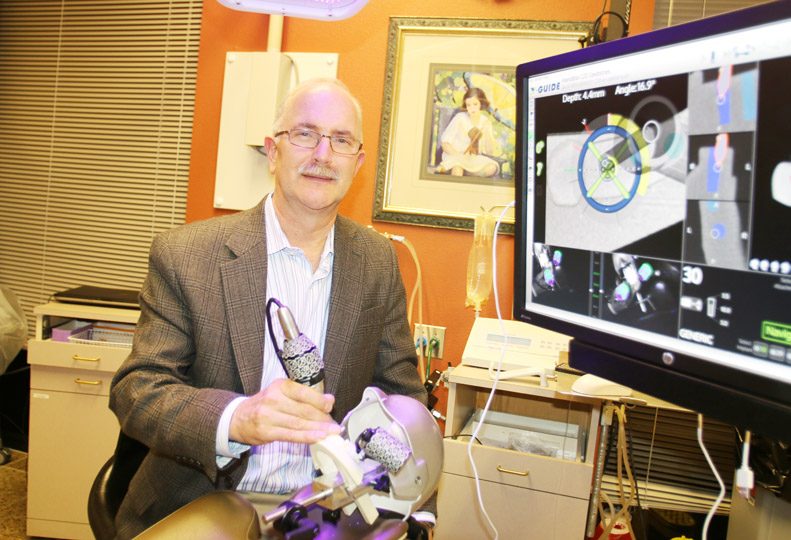

Dr. Daniel R. Cullum, oral surgeon and founder of Coeur d’Alene-based Implants Northwest, is pioneering the use of a computer-guided system for precision placement of dental implants.

The X-Guide navigational guidance system, which the manufacturer describes to oral surgeons as being “like GPS for your drill,” enables surgeons to improve the accuracy of implant position, angle, and depth, Cullum says.

Implants Northwest and two other specialty dental practices were part of trials overseen by an Institutional Review Board beginning in April 2015. The U.S. Food and Drug Administration approved the new navigational guide technology in October 2015, although the investigative study is ongoing.

“We were able to use it on patients to provide data used to get FDA approval,” Cullum says.

Implants Northwest occupies 4,500 square feet of space in a multitenant building at 1859 N. Lakewood Drive, in the Riverstone development. The practice, which has a support staff of 10, also has a satellite office in Sandpoint, where Cullum practices one day a week.

The primary focus of the practice is dental implants, although Cullum also performs extractions and some trauma procedures.

Dental implants typically are titanium posts that act as artificial tooth roots and anchor replacement teeth to the jawbones. Implants come in a variety of sizes, shapes, and thread patterns to fit most any angle and depth required for best outcomes, Cullum says.

The new navigational process for planning and performing implant surgery starts with what’s called a cone-beam computed tomography scan that converts X-ray data into 3-D images of the implant site, including surrounding teeth and underlying bones.

“We can see the images in 3-D, and we can actually plan to put implants of exact shape and size in position,” Cullum says.

The guidance system components include a hand-piece tracker, which is a collar on the drill handle marked with a matrix pattern resembling a series of QR codes. A patient-tracker cylinder with a similar-looking pattern has an attachment made to fit on a reference point within a patient’s jaw.

The X-Guide system uses a stereo camera to monitor the movements of the trackers. The system overlays a live animation of the drill bit and the implant site on the planning image created earlier from the CT scan.

When the surgeon begins to drill, the system zooms in and provides guidance information through graphics similar to a targeting system on a military aircraft.

“Now, instead of looking at the patient while doing surgery, I’m looking at the screen,” Cullum says. “It gives me a bull’s-eye target. It shows the angle, and tilt, and depth.”

The implant process generally involves two visits, with the first visit consisting of imaging and planning and the second visit being the surgery, Cullum says.

He adds, however, “We do have some folks who come from Sandpoint or greater distances and want it all in one day.”

For the most part, it takes at least three months for bone tissue to heal and integrate with the implant, before a permanent dental crown can be attached to it. In a few situations, Cullum says, temporary teeth can be installed on the posts for aesthetic reasons, although they aren’t functional for chewing.

A patient’s regular dentist or a restorative dentist usually fits a permanent dental crown on the implant after the bone surrounding the implant heals from the surgery.

“I’m a specialist with a referral practice,” Cullum says. “I do implants for other doctors who do the (replacement) teeth on top of them.”

Prior to having access to the navigational guide technology, Cullum says he would view a CT scan and use software to map out the implant location in a surgery plan. But the most direct way he could integrate the plan in the surgical procedure—as opposed to freehand drilling—would be to send the plan, along with the patient’s dental impressions, out to a lab, which would mill a static guide to fit over the implant site with a hole to guide the drill bit.

“With fabrication and shipping costs, it’s expensive when we have to send it out to make the guide,” he says. “Then, if we get it back and it doesn’t fit, we have nothing.”

With the X-Guide system, Cullum says he can change the surgery plan in mid-procedure if he sees a need to make adjustments for the implant site.

“I can go to the navigation machine and change it and have a new reference to drill or put it in a new spot,” he says.

Using the X-Guide, Cullum maintains full manual control of the drill, although the navigational guide enables him to achieve greater accuracy.

“This lets me have maximum control to make sure I’m putting the implant in the right place so that it will heal well and be positioned right for the final tooth so it looks normal.”

X-Guide promotional material claims surgeons using the navigational system can expect to achieve angular drilling accuracy “approximately 11 times better than freehand” and 3-D positional accuracy nearly two times better than with a static guide.

X-Guide, which is made by X-Nav Technologies LLC, of Lansdale, Pa., is the first implant system to use the navigational guidance technology.

The total system requires a cone-beam CT scanner, planning software, and the X-Guide components.

Cullum estimates the total cost for the system at between $150,000 and $200,000.

“It’s just now crossing into the mainstream,” Cullum says, adding, “It’s been limited because the company can only make so many units per month. I think they have 30 installed now.”

He says the X-Guide system doesn’t add to the cost of implant procedures performed at Implants Northwest.

“It’s an investment that helps me do higher-quality surgery. I can do a larger number of cases with it, so the efficiency is helpful,” he says.

The cost for implants through Implants Northwest starts at about $2,000, which doesn’t include the cost of the permanent crowns attached to implants by a patient’s dentist.

If patients have insurance that includes implant coverage, the coverage wouldn’t change with use of the X-Guide system. “Because I don’t assess anybody an extra fee for using the navigational part, it doesn’t change that dynamic,” he says.

Cullum says the X-Guide system is an adjunct to minimally invasive techniques.

To employ minimally invasive implant techniques, the surgeon must learn how to do surgery by feel without lifting up the skin or gum to expose the implant site, he says.

“Now I can do it by feel, plus the navigation is telling me dimensionally where I am and gives me a whole new set of data points to make sure I’m accurate,” he says.

Latest News Health Care Technology North Idaho

Related Articles

![Brad head shot[1] web](https://www.spokanejournal.com/ext/resources/2025/03/10/thumb/Brad-Head-Shot[1]_web.jpg?1741642753)