Home » Peirone Produce boosts efficiency at new warehouse

Peirone Produce boosts efficiency at new warehouse

Big West Plains facility boasts three times as many loading docks

July 15, 2010

After moving to a new, much larger facility on the West Plains this spring, Spokane-based distributor Peirone Produce Co. says it already has seen vast improvements in its efficiency in getting orders of fresh produce from its warehouse to the regional grocery stores it serves.

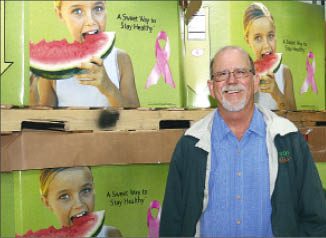

"It has allowed us to grow our business and has improved productivity," says Peirone President and CEO Pat Davidson.

The new facility, located at 9818 W. Hallett Road, just east of the Interstate 90-Medical Lake interchange, has 70,000 square feet of warehouse space and 7,000 square feet of office space, Davidson says.

"It's two and a half times the size of our old location," he says.

For more than 40 years, Peirone Produce had occupied a 28,500-square-foot office-warehouse building at 524 E. Trent.

The new warehouse has 14 docks for loading outgoing trucks, and 12 docks for unloading incoming produce, compared with a total of eight docks at its former location for both incoming and outgoing orders, says Jim Morrow, Peirone's operations manager.

The increased number of docks enables workers to gather orders and load them onto outbound trucks in a total of about eight hours, rather than the 11 hours or more it took at the older facility, he says.

After the move to the West Plains facility, Peirone hired about eight more workers, Davidson says.

Telephone orders from the company's clients usually are received by 4 p.m. each day, and are entered into a computer system, Davidson says. Workers in the warehouse then start pulling all the produce needed to fulfill the orders from the different coolers and stacking it near the loading docks. He says the trucks usually are loaded and rolling out of the warehouse by midnight, and deliveries are completed by 8 a.m.

The company installed a new computer system for order entry and distribution management last October and has been using the system at its new location, Davidson says.

"It brought us up to date on the technology that is available in our industry," he says.

Warehouse employees are able to access orders electronically and print out orders for reference as they gather produce from the warehouse for distribution, he says.

Another upgrade put in place at the new location is the tightly sealed doors at each dock that remain closed until the trucks are in place, preventing the loss of cold air from inside and the invasion of warm air from outside, Morrow says.

One of the most important things in produce transportation and distribution is ensuring that the "cold chain," which is the term used to describe the maintenance of the controlled air temperature in every environment where the produce is kept or transported, isn't broken, Davidson says.

"It wasn't like this at the old warehouse. Here we have improved it 110 percent in terms of keeping the cold chain," Morrow says.

New features that enable the company to maintain that cold chain are among the biggest benefits of the new facility.

Computer-controlled refrigeration systems installed at the warehouse allow more efficient control over each individually controlled chamber and room in the warehouse, he says.

In one of those rooms, several huge, yellow rolling doors enclose chambers of towering stacks of bananas imported from Honduras while they are still green. The temperature system is set to precise levels that are optimum for the bananas to ripen before they are shipped out, Davidson says. A similar setup ripens tomatoes at the warehouse, which also are received green. The tomatoes are ripened behind red doors.

The new system also allows Davidson to monitor the temperature of any area of the warehouse through his laptop or cell phone, he says, and alerts him of any temperature failures.

Peirone also has implemented several new "green" practices, such as recycling cardboard and composting organic products that have been damaged during transportation.

"The new facility is substantially greener. We are doing 100 percent more recycling," Davidson says.

All of the produce that is transported to and from Peirone Produce is never at the warehouse longer than three days, and usually only stays for about two and a half days on average, he says.

Peirone owns a fleet of 26 tractor-trailers with 53-foot-long refrigerated compartments and four 20-foot-long refrigerated trucks, Morrow says.

A 6,000-square-foot maintenance facility for the company's truck fleet also was constructed at the new facility, Davidson says.

Between 10 and 15 incoming trucks deliver produce to the Peirone facility each day. The incoming trucks include contracted carriers and also Peirone's own rigs, bringing in commodities from as far as California, Arizona, Texas, and the US-Mexico border, he says.

Peirone distributes to grocery stores operated by Rosauers Supermarkets Inc., Yoke's Foods Inc., Super 1 Foods, Trading Co. Stores, Harvest Foods, and several other independent chains, Davidson says. The company serves Eastern Washington, North Idaho, Western Montana, and parts of northeastern Oregon.

Davidson says that his company has noticed some impact from the economic recession, but that it hasn't been anything significant.

Peirone Produce was founded in 1946 by Jim Peirone and has been owned by URM Stores Inc. since 1986.

The company currently employs 91 people and generally has around 100 employees, depending on the season, Davidson says.

Latest News

Related Articles