Home » Idaho aerospace alliance takes off

Idaho aerospace alliance takes off

Alliance aims to secure share of hot industry

March 29, 2012

North Idaho aerospace manufacturers have launched an effort to form a statewide coalition and develop strategies to attract and keep aerospace-related business in Idaho.

The idea for the recently created Idaho Aerospace Alliance, which has a dozen member companies and agencies and is still in its formative stage, was triggered byan Idaho inquiry into the impact of the aerospace industry in North Idaho, says Jim Glenn, president of Titan Spring Inc., of Hayden.

"Some manufacturers got together and decided we needed to form an industry association for our own purposes," says Glenn, who also is chairman of the alliance.

Titan Spring, which moved its operations to Hayden from Southern California in 2007, employs 30 people and occupies 16,000 square feet of floor space at in the Warren K Industrial Park west of U.S. 95, in Hayden.

Greg Seibert, Boise-based economic development specialist with the Idaho Department of Commerce, says an initial census of the aerospace industry in North Idaho identified at least 374 jobs in aircraft manufacturing alone. The department wants to ensure Idaho nets a share of what it expects to be a strong growth industry with good-paying jobs for years to come, he says.

Also, the department is working with two aerospace companies he declines to identify that are planning expansion projects in North Idaho.

The Idaho Department of Commerce plans to participate in the alliance as a nonvoting member, Seibert says. He and Commerce Director Jeffery Sayer attended an alliance meeting earlier this month at the Idaho Department of Labor office in Post Falls. The state labor department also is providing some administrative assistance to the alliance, Seibert says.

Glenn says one of the first tasks of the alliance is to identify the companies conducting aerospace work, what their needs are, and how to promote trade between companies.

"I might be sending some work to California that I might be able to have done here," he says.

Glenn says many people are surprised to find out that the majority of Titan Spring's production goes to aerospace and defense customers or their suppliers.

"When I give people tours, they are blown away by how much aerospace-related work we do," he says.

The alliance will enhance informal networking currently occurring, Glenn says. For instance, Titan Spring works with Cygnus Inc., a Ponderay, Idaho, manufacturer of sheet metal parts and assemblies for the aerospace industry, he says. Cygnus also supplies Unitech Composites & Structures, of Hayden, with certain metal parts that go on its composite assemblies.

"We're still in the discovery phase of finding out what's here, and we're starting to get people from Boise contacting us with interest," he says, adding, "The alliance was born here, but it will go statewide."

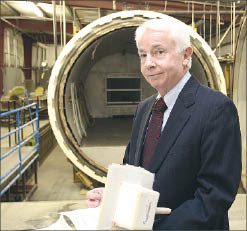

Unitech Composites & Structures, a charter member of the alliance, is seeing rapid growth, says Rick Hundley, company president.

The company's revenues have increased at a steady rate of 20 percent a year for the last few years, Hundley says.

Unitech, part of the Oklahoma City-based AGC Composites Group, makes composite parts, including ballistic and interior panels, structural parts, duct systems, subassemblies, and detail parts for several types of aircraft. Composites are materials made with resin and reinforcing strands, such as fiberglass reinforced plastics. Often, composites are lighter, stronger, and more durable than metal parts with the same dimensions. Such characteristics of composites help improve aircraft performance and reduce operating costs, Hundley says.

Last year, Unitech's sales were about evenly split between military and commercial markets.

This year, 65 percent of its revenue will be from the commercial market as Boeing Co. ramps up production of its 787 Dreamliner jumbo jet. Each 787 aircraft has more than 1,100 parts made by Unitech, he says.

Boeing recently announced it will increase its 787 production to 3.5 planes a month, and it has hundreds of the planes on order, which Hundley says provides some measure of security for Unitech for a number of years.

Boeing is by far the largest end customer of Unitech's products, he says.

Also, Unitech soon will be qualified to manufacture parts for the Airbus A350, the main competition to the Boeing 787, Hundley says. He expects a small contract to begin the certification process.

The company has 130 employees, and is on an upward employment trend.

"We're looking for a few additional people now," Hundley says. "We hope to have around 200 employees by the end of the year."

Hundley says the Idaho Aerospace Alliance will help members address common challenges within the aerospace manufacturing industry.

"One objective is to improve the quality of training," he says.

Unitech and North Idaho College will kick off a program within a couple of weeks to train quality employees to become supervisors, enabling them to advance within the company. Unitech also has submitted a training grant application to the state, Hundley says.

He says he expects Unitech will outgrow its current facilities, at 10413 N. Aero Drive, in Hayden, near the Coeur d'Alene Airport, where it occupies 87,000 square feet of leased space in several buildings

"Within the next two years, we would like to build a completely new facility that would be larger by about a third," he says.

Not all North Idaho aerospace companies, however, have fared as well through the recession.

Business at Space Screw Inc., of Rathdrum, has picked up in the last nine months, but Kevin Bates, quality and production manager there, says it was terrible through recession.

"We had a rough 3 1/2 years, but we're making money now, and business is increasing," Bates says.

Space Screw fabricates precision screw machining components for aerospace, telecommunications, medical, high-performance, and industrial markets. The company currently employs 10 people and occupies a 12,000-square-foot facility.

Bates has been attending Idaho Aerospace Alliance meetings and says he hopes it will help bring more business to Space Screw.

"We're looking forward to possibly getting more work and getting to know other aerospace manufacturers in the area," Bates says. "It's been good meeting to talk about issues."

Other members of the alliance include Aerocet Inc., of Priest River; Empire Aerospace, of Hayden; Lightning Tool & Manufacturing Inc., of Post Falls; and Quest Aircraft Co., of Sandpoint.

The alliance also could help attract other businesses to Idaho, he says, adding that Idaho offers several advantages for manufacturers compared to some other states.

"If we were making springs in California, we would be paying five times more for workers comp than we're paying here," Glenn says.

Other benefits of being based in Idaho include lower cost of electricity and housing, he says.

Latest News

Related Articles