Home » Kaiser ramps up plant investment at Trentwood

Kaiser ramps up plant investment at Trentwood

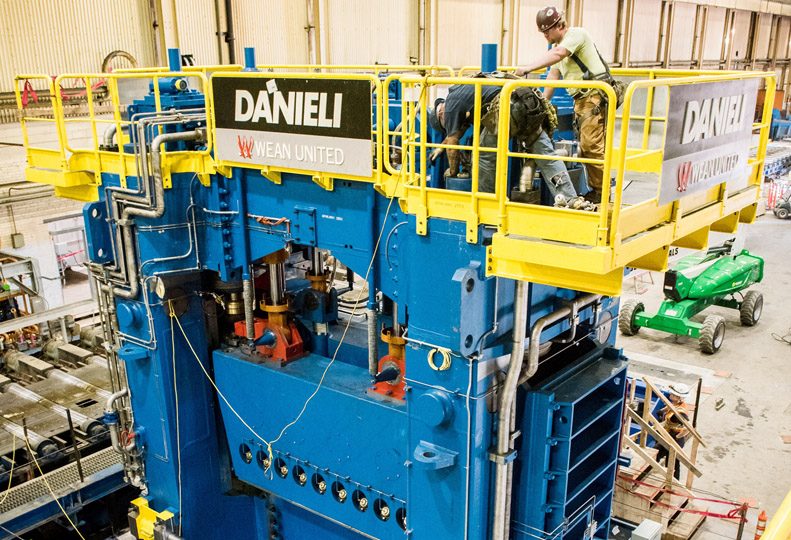

Massive plate shear part of $150 million in improvements

May 11, 2017

Kaiser Aluminum Corp. officials say the company has started spending more aggressively on the $150 million investment the company has committed to at its Trentwood plant in Spokane Valley.

Kaiser announced near the end of 2015 it would be investing the money over a five-year period starting in 2016.

“We’re bringing a lot of the modernization online this year,” says Scott Endres, vice president for Kaiser’s flat-rolled products.

Kaiser says the investments are expected to provide a 5 percent to 10 percent increase in Trentwood’s manufacturing capacity by early next year.

The most substantial work to date involves installing an approximately three-story plate shear, which will help make the aluminum plate-rolling process faster and more efficient, Endres says.

When finished, the shear will have the ability to more quickly cut large aluminum plates into smaller pieces, which are then sold to the company’s customers. Boeing Co. and French-based Airbus are two of Kaiser Aluminum’s largest global buyers.

Kyle England, Kaiser’s human resources manager, declines to disclose the cost of individual projects and new machine costs.

Founded in 1946, Kaiser manufactures plate, sheet, and coil products specially tailored for the aerospace and high-strength markets. Kaiser has 12 manufacturing facilities in the U.S. and one in Canada. The company’s corporate headquarters are located in Foothill Ranch, Calif.

Most of the construction on the three-story plate shear will be finished this year, and that project will be fully completed in 2019, Endres says.

“We will begin to realize benefits from the project in the form of efficiency and capacity in 2018,” he says.

“We say around here, ‘We compete with everyone, everyday … forever.’ We have to be more efficient,” he adds.

Before starting the current $150 million round of upgrades, Kaiser invested $240 million in infrastructure improvements to update the World War II-era factory between 2005 and 2015.

The Trentwood facility is located at 15000 E. Euclid and employs 900 people. It has 60 acres under roof and occupies a total of 515 acres of land. Endres says it’s the largest flat-rolled aluminum mill in the western U.S.

“The Trentwood strategic investment and modernization product project is proceeding as planned, and the facility is now preparing to embark upon more significant construction activities and equipment outages scheduled for the second quarter,” company CEO and Chairman Jack A. Hockema said in a press release discussing the company’s first-quarter financial performance.

“As we’ve previously discussed, and consistent with our first half 2017 outlook, construction activity will have a significant impact on our second quarter results as we complete this next phase to expand capacity and improve our competitive cost position,” Hockema said.

Kaiser says it posted record revenue of $813 million in 2016, up 3 percent from $790 million, also a record, in 2015 and from $733 million in 2014.

For 2016, the company reported a net income of $92 million, compared with a net loss of $237 million the prior year.

“As we look to our aerospace, high-strength applications, real end-user demand growth is expected to be strong over the next three years, driven by continued growth in commercial aerospace builds, recovering growth for business jets, and solid growth for military aircraft due to the Joint Strike Fighter and international demand for prior generation aircraft,” Hockema said.

He said, however, that the company expects 2017 to be a challenging year due to rising metal costs and the scheduled construction and equipment outages at the Trentwood plant.

Said Hockema, “We anticipate that our manufacturing efficiency during the first nine months of 2017 will fall short of the record 2016 performance level.”

Endres says there’s been more competition in the last decade than ever before in the global aluminum manufacturing industry.

“Russia, China, Europe, and smaller emerging mills in the U.S. have all entered the marketplace and want a share of the business from the Boeings and Airbuses of the world,” he says. “We’re positioned to grow as markets grow.”

Referring to constructed airplane parts and components, Ronald Weiss, Kaiser’s vice president for marketing-flat-rolled products, says, “If it’s built in the Western world, then we’re on it.”

Meanwhile, England, says the company is continuing to be more proactive in a variety of areas as it does business.

Company executives meet regularly with representatives from Greater Spokane Incorporated, the Washington governor’s office, the state Department of Ecology and environmental organizations to address ways to continue improving recycling efforts and lowering carbon emissions generated at the plant.

It takes 1,700 to 2,000 degrees Fahrenheit to melt aluminum and involves an intensive process that can’t be achieved through solar or wind energy, England says.

Endres says, “We’re actively engaged with all the stakeholders and are eager to be a part of the solutions both economically and environmentally.”

Latest News Manufacturing

Related Articles