Home » Growth by diversifying

Growth by diversifying

Wilbert Precast, once known for burial vaults, now makes a host of concrete products

February 26, 2009

Wilbert Precast Inc., a longtime Spokane-based manufacturer of concrete products, says it's holding its own amidst a tough economy because it has been quick to expand its offerings as opportunities arise, giving it a diverse product line upon which to rely today.

Once known mostly for making burial vaults and building mausoleums, Wilbert Precast has been evolving since 1975 to produce a host of concrete products ranging from septic tanks and manholes to window wells and retaining-wall blocks.

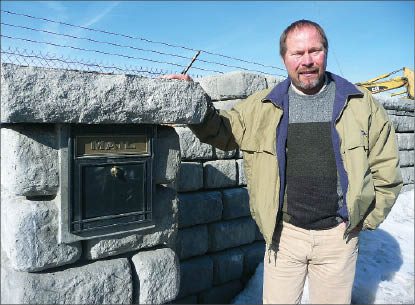

In one of its more recent product additions, the company began making stone-look blocks for use in retaining walls, columns, steps, and block paving under a dealer agreement with Charlevoix, Mich.-based Redi-Rock International. Wilbert took on the product five years ago, and already is one of the top five Redi-Rock dealers in the U.S., having sold 25,000 blocks last year for revenue of about $2 million, says Dan Houk, the Spokane company's president and CEO. The company could make as many as 40,000 blocks this year, depending on the economy, Houk says.

The company, founded in 1906, has its main facilities at 2215 E. Brooklyn, north of the Hillyard area. There, it employs about 70 full-time workers. In addition, it employs about 40 workers at a plant in Yakima, Wash., and another 10 employees at an operation in Lewiston, Idaho, for an overall work force of about 120 people. That number is up modestly from three years ago, Houk says.

Last year, the company had sales of about $15 million, up slightly from about $13 million in the previous year.

In addition to the concrete products it now makes, which also include utility-meter vaults, custom castings, and light-pole bases for parking lots, Wilbert Precast also continues to design and construct burial niches for cremation remains, as well as complete mausoleums. It currently is doing a $270,000 such project in Kennewick, Wash.

Wilbert Precast began making light-pole bases just three years ago, after it decided it could make a better and less expensive product than what it was seeing in the field. Sales of that product since have increased rapidly, and are expected to continue to do so, Houk says.

The company sold about 800 such bases in the first year it offered the product, and another 1,300 last year, he says.

"It's a new and growing area for us," Houk says.

The company also recently began manufacturing storm-water treatment systems under an agreement with the systems' developer, Buffalo, N.Y.-based Environment 21, Houk says. Wilbert so far has sold systems to a water district in Oregon and for a new Lowe's store in Moses Lake, but has begun actively marketing them to developers and government agencies throughout the region.

The treatment systems, which are housed in large concrete structures, are intended to take the place of the grassy swales seen along parking lots and other developments. They are intended to filter storm-water runoff of some impurities, before it percolates into the ground or washes into rivers or lakes.

Brock Materne, a project coordinator at Wilbert, says swales use up valuable real estate, and developers might find the storm-water treatment systems preferable.

"We wanted to be able to offer some type of stormwater treatment products, and Environment 21 was the right fit," Materne says. "It also adds to our product line. Some of our competitors offer some type of storm-water treatment systems."

Houk says adding new product lines and getting rid of a few along the way—such as concrete hitching posts for horses—keeps the company growing and prospering.

After acquiring Yakima Precast Inc. in 2006, Wilbert Precast opened a new 24,000-square-foot facility for its operation there in January 2008, on 15 acres of land it had purchased. The company had been operating a plant in Yakima since the early 1980s, but built the new facility there to consolidate that operation with that of Yakima Precast. The Yakima operation continues to be the company's hub for all of central Washington.

The Lewiston manufacturing plant was built in 1999.

Latest News

Related Articles