Home » Bootmakers don't miss a step

Bootmakers don't miss a step

White's, Nick's, and Cruz here, Hoffman, in Kellogg, march on

December 23, 2009

Inland Northwest companies that sell handmade work boots have seen once dependable customer bases—including loggers—shrink, but have continued to march ahead thanks to the durability of other markets.

Meanwhile, those specialty manufacturers also have been battling the effects of the recession, adjusting to changing customer demands, and competing with makers of less-expensive, mass-produced boots from overseas. Yet, the longtime businesses here have weathered bad economies before, and so far through the current downturn, they've largely been able to maintain steady sales and staff levels.

Spokane is home to such well-known makers of handcrafted boots as White's Boots Inc., the longtime manufacturer located at 4002 E. Ferry; Nick's Custom Boots Inc., at 3805 N. Market, which was established here in 1964 by the late Nick Blahcuzyn; and the small Cruz Shoe Shop, at 209 W. Main. In Kellogg, Idaho, Hoffman Boots Inc. makes its home.

"You could probably count on both hands the number of handmade boot manufacturers here in the U.S.," says Frank Petrilli, Nick's general manager.

Says Hoffman Boots part owner Beth Hoffman, "More and more people want to try and buy an American made product. They want to support people in our own country."

Still, handmade boots are hard to find, says Hoffman, who owns the Silver Valley business with her brothers, Jim and Tom Hoffman. "Most stuff is imported from China," she says.

White's is the biggest of the bootmakers here, with about 110 employees, and it, along with Nick's and Hoffman, employs a total of about 150 people.

White's President and CEO Gary March wasn't available for an interview, but the venerable company says on its Web site that its roots go back to before the Civil War and to West Virginia, where Otto White's father and grandfather made boots for the logging industry. Otto White and his father moved the business to St. Maries, Idaho, in 1902, then it was moved to Spokane in 1915, and Otto White remained active in the business until his death at age 91 in 1972.

White's was long known as the boot company that would trace an outline of each of your feet when you placed an order, and even today, its catalog includes a form on which customers can trace the outlines of their feet.

White's connection to the U.S. Forest Service's smokejumpers goes back so far that the company's Web site includes a link to the National Smokejumpers Association and the online Wildfire Photo Journal, which features dramatic pictures of Hot Shot Crews and other firefighters.

"There's a phrase in smokejumping called 'hanging up your White's,'" when a jumper retires and ends his career of parachuting out of airplanes to fight forest fires in remote locations, says Steve Smith, a historian and representative for the association.

Bill Moody, of Twisp, Wash., who's now 70, bought his first pair of White's in 1960 when he began his smokejumping career in the North Cascades. During his 33 years of smokejumping he had four pairs, though White's rebuilt his boots often.

"You'd get them back almost new," he says. When he did get new pairs he would almost immediately jump in a creek or some water and get them soaking wet, then wear them in the heat while he worked to get them into a perfect form fit, he says.

White's provided great support for the jumping, "stood up in the fire environment" with the high heat and ash, and were excellent for hiking out of remote locations, Moody says.

White's, which also makes the Hathorn line of boots, produces specialty boots for loggers, farmers, ranchers, hunters, and others, including high-topped models for linemen who wear climbing spurs while they climb wooden utility poles.

Doug Tweedy, regional labor economist for the Washington state Department of Employment Security here, remembers White's Boots from his days of doing ranch work as a young man, and says he's noticed the cadre of makers of high-quality boots here.

"That kind of speaks to the diversity we have of small manufacturers here," says Tweedy. It takes skilled craftsmen to make boots and staff such businesses because "a lot of things have to be done in the way of labor." That capability "helps us along during the recession," he adds.

The bootmakers' products here "are very high quality, and they have a lot of good services. That's a direct opposite of where some of the stores are heading."

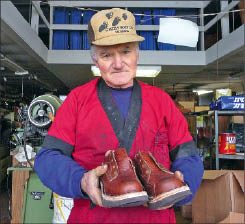

Among the bootmakers here is Cruz Albisu, owner of Grizzly Boot Co. and Cruz Shoe Shop, at 209 W. Main. Albisu says he has been making boots and some shoes here since 1970. His Grizzly Boot brand is sold by 350 dealers in 14 states, he says. He makes cowboy, logger, linemen, and smokejumper boots and so-called "pack" boots for working in snow.

Currently, he's a one-man show, crafting 400 pairs of boots this year in his 4,000-square-foot space downtown.

"One man can only do so much," Albisu says. "It's been slow this year. Last year was better."

Cruz, who is originally from Spain, says he hopes to increase production to 4,000 boots in 2010, when he anticipates having three or four employees.

"There's enough equipment here for 50 people to work," he says.

Petrilli says Nick's currently employs 20 people, and operates in a 6,000-square-foot space. He declines to provide sales numbers or to say how many boots the company makes.

The company hasn't cut any positions during the recession, he says. "We haven't seen the rises and dips that other parts of the country have seen," he says.

The company makes boots for all trades, though its linemen's boots and wild-land firefighter boots have been selling much better than its logger boots.

Its boots are sold all over the country by a network of vendors, plus Nick's has a retail presence here, Petrilli says.

Manufacturing has been going at a steady pace, though sales have slipped a bit, he says. The average price of a pair of Nick's boots is $350.

Petrilli says the company maintains an inventory of popular sizes and styles, and if a new pair must be manufactured it takes about eight weeks, "because of the demand on production."

It takes about eight hours to make each boot, not counting drying time.

"We handmake them one at a time," he says. "This is not an assembly-line type of an operation. We move a little bit slower than most."

Its repair business is going strong, he says.

"With the recession, we've seen the repairs increase," because many customers have been choosing to hold off on buying new boots, Petrilli says.

What Petrilli has noticed with some disappointment, he says, is that more and more boots are being made overseas. "I'd like to see it come back over here," he says.

Hoffman has been churning out about 80 boots a day, about 70 of those for linemen, says Beth Hoffman.

The company employs 12 people and operates in a 12,000-square-foot building. Its boots are sold at about 200 stores nationwide.

Along with its linemen's boots, Hoffman makes hunting, firefighting, and logging boots. It also now makes a boot for military special-forces personnel that's similar to its linemen boots, she says.

"The logging industry has gone down so much," she says. "The linemen business has really taken off."

She says more than 100 individual steps go into making a winter linemen's boot, and it takes two days alone to make the sole, she says.

The linemen boots range from about $200 to more than $300, the company's Web site says.

Hoffman declines to say what sales have been, but says, "We've actually grown," despite the recession.

White's sells other Northwest lines of products for people who work outside, including Filson coats and Pendleton wool shirts and blankets.

Latest News

Related Articles